North America

We hold a unique American story that remains an integral part of U.S. history and what the U.S. National Security Mission stands for today. Having designed, constructed, and operated much of our United States infrastructure that still thrives, we have continually provided management and operations, along with the security force protecting this U.S. infrastructure, critical to national security. As the longest-operating U.S. engineering firm, we bring nearly 200 years of history, with 120 of those years serving as the trusted partner to the U.S. Department of Defense and other agencies. In addition, we have proudly served the Department of Energy mission on more than 100 contracts for more than 75 years. Today, our mission-critical designs and integrated security keep U.S. personnel, property, and assets in the U.S. and overseas safe.

Building a More Secure World®

200 Years as the Longest Operating American Engineering Firm Supporting the U.S. Federal Government 120+ Years of A/E Experience supporting the Department of Defense

120+ Years of A/E Experience supporting the Department of Defense .png?width=99&height=99&name=MapMe%20Stat%20Icons%20(2).png)

75+ Years Supporting the DOE

.png?width=100&height=100&name=MapMe%20Stat%20Icons%20(8).png) 100+ Contracts for DOE

100+ Contracts for DOE

40+ Years O&M Services For Army's Largest Ammunition Storage & Demil in the World

80,000+ Tons of Safely Demilitarized Ammunition, Since 2010

- placeholder tgext

.png?width=100&height=100&name=200%20years%20%20(1).png) 30+ Years Supporting the U.S. National Intelligence Mission

30+ Years Supporting the U.S. National Intelligence Mission- PLACEHOLDER TEXT

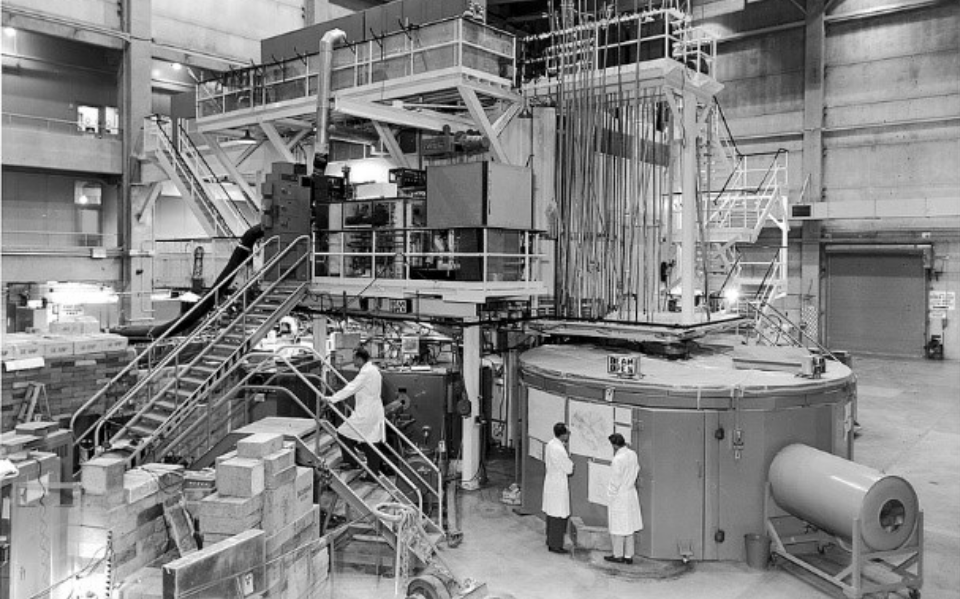

Supporting the Department of Energy (DOE)

Serving the DOE for More Than 75 Years

Our History

Since 1947, we have provided an array of architectural, engineering, and security services to the Department of Energy (DOE) —from the design of nuclear weapon manufacturing plants in the 1950s to the ongoing protection of present-day facilities including the Burlington Plant, Pantex Plant, and Nevada National Security Site.

For more than, 45 years, we've provided management & operations (M&O) services at the Pantex Plant in support of the DOE. We've also filled a critical role by providing nearly 40 years of protective force services safeguarding national security assets starting with the Los Alamos National Laboratory (LANL).

Fulfilling a Mission-Critical Role

Pantex Plant

In 1947, Mason & Hanger designed (A/E) the Pantex Plant. For more than four decades (1956-2011), we provided management & operations (M&O) services at the mission-critical plant.

SOC provides award-winning protective force operations in support of the Pantex site including perimeter control, static guards, access control, Special Response Teams, Fire, EMS, and Hazmat operations. SOC is a member of the team providing management and operations for the Pantex Plant, in support of the U.S. Department of Energy, National Nuclear Security Administration (DOE/NNSA). Pantex is one of six production facilities in the NNSA’s Nuclear Security Enterprise. In 1947, Mason & Hanger designed Pantex and provided management & operations (M&O) services more than four decades (1956-2011).

Safeguarding & Securing Critical Security Assets

Strategic Petroleum Reserve (SPR)

SOC serves as the Protective Force (Proforce) for the Reserve with Critical Infrastructure Security Services. Fluor Federal Petroleum Operations (FFPO) is the current management and operating contractor. The SPR is the world's largest supply of emergency crude oil established primarily to reduce the impact of disruptions in supplies of petroleum products, in order to carry out U.S. obligations under the international energy program. The SPR encompasses crude oil storage sites located across Louisiana and Texas, and the project management office (PMO) headquartered in New Orleans.

Designing Training Facilities For Today's Threat

Designing for the U.S. Department of State

Foreign Affairs Security Training Center (FASTC)

At FASTC, we filled the role of tactical training consultant, providing architectural and engineering design for the 14 hard skills (tactical training) structures, which include a mock embassy compound, three indoor firing ranges and an outdoor 100M range, a live fire shoot house, 14-bay vehicle maintenance shop and a rappel tower. We established a facility to conduct hard skills training focused on embassy security at one location.

Counter-Terrorism Training Facility

Federal Law Enforcement Training Center (FLETC)

The Federal Law Enforcement Training Center (FLETC) serves as an interagency law enforcement training organization for more than 80 Federal agencies as well as state, local, tribal, and international law enforcement agencies. Mason & Hanger provided design services for a training site on the Glynco campus that provides a realistic training environment which simulates real world conditions as closely as possible.

Supporting the Asymmetric Warfare Group (AWG) Mission

Asymmetric Warfare Training Center

Mason & Hanger performed complete architectural and engineering design services for the 426-acre campus built to test new Tactics, Techniques and Procedures (TTP’s) to meet the asymmetric threat soldiers encounter on the battlefield. The Complex is divided into two main areas: the Range Support/Cantonment Area (occupied buildings), containing the administrative, training, housing, maintenance, fabrication, and arms building, and the Battle Lab Area, including utilitarian buildings to support testing different scenarios.

Providing Mission-Critical Support to the U.S. Government

Partnering With NASA

Flight Dynamics Research Facility (FDRF)

Mason & Hanger is a contributing partner on the design-build contract of NASA's new Flight Dynamics Research Facility (FDRF) at the Langley Research Center in Hampton, Virginia. We are working in partnership with BL Harbert International (BLHI) and Calspan Aero Systems Engineering, Inc. The new wind tunnel will provide researchers with a highly versatile and cost-effective vertical wind tunnel for conducting research and technology development that supports diverse NASA missions, including aeronautics research, space exploration, and science.

.jpg)

Munitions Modernization Services for Military Partners

Naval Surface Warfare Center (NSWC) Indian Head

Mason & Hanger is a leader in providing planning, design, engineering, and construction support services for munitions and industrial facilities for the United States Army Corps of Engineers and the United States Navy as well as other government agencies. For more than 30 years, we have provided design and engineering services for the Naval Surface Warfare Center (NSWC) in Indian Head Maryland.

Demilitarized Ammunitions Since 2010

Hawthorne Army Depot (HWAD)

SOC provided 40 years of Operations & Maintenance (O&M) services for the Hawthorne Army Depot as the operating contractor for the U.S. Army’s facility with the largest capability for premier R3 (resource, recovery, and recycle) ammunition storage and demilitarization in the world. The company provided munitions operations, base operations, equipment management, environment, safety and health, technical security and security systems monitoring, and protective services in addition to safely demilitarizing more than 80,000 tons of ammunition, since 2010.

Supporting The Intelligence Community

Managed Staffing Services

SOC’s Cleared Staffing Solutions delivers highly cleared Software Developers in support of the Development and Enhancements for Enterprise Applications (DEEA) contract supporting the Defense Intelligence Agency’s (DIA) continuing transition to the Intelligence Community Information Technology Environment (IC ITE), Joint Information Environment (JIE) and other IC IT modernization efforts.

Preventative Maintenance, Repair & Overhaul for the U.S. Government

New Boston, Texas

SOC provides vehicle maintenance solutions with quality, reliable, technical services at our New Boston, Texas maintenance facility, delivering vehicle maintenance qualifications, field team deployment, and program management experience bolstered by our ISO 9001:2015/AS9110C certified quality management system (QMS). We provide large vehicle refurbishment (such as HMMWV, HEMTT), MWO installation, parts fabrication and painting to 10/20 standards for delivery of completed vehicles to the U.S. and our Allies.

We have provided mission support for the U.S. Government in the following states:

- Alaska

- Alabama

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- District of Columbia

- Florida

- Georgia

- Hawaii

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Louisiana

- Massachusetts

- Maine

- Maryland

- Michigan

- Minnesota

- Missouri

- Mississippi

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Mexico

- New Jersey

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Virginia

- Washington

- West Virginia

- Wisconsin

- British Virgin Islands