Serving the Department of Energy for More Than 75 Years

We have proudly served the Department of

Energy and DOE mission for more than 75 years.

Since 1947, we have provided an array of architectural, engineering, and security services—from the design of nuclear weapon manufacturing plants in the 1950s to the ongoing protection of present-day facilities.

More Than 75 Years of History

1947 - 1975

Burlington Plant

In 1947, we begin operation of the Atomic Energy Commission’s (AEC) Burlington Plant in Iowa, the AEC’s first production plant for high explosive components for nuclear weapons.

World War II and the Korean War sparked an increase in weapons production and the need for supporting chemistry, physics and electronics technologies. We responded, and our engineers played a critical role in developing the Department of Energy and Atomic Energy Commission’s weapons. At the same time, we became a trusted partner in the research and development, manufacturing and production, and testing and retiring of stockpiled nuclear weapons.

Mason & Hanger supported operations and production of nuclear weapons until 1975, when operations were transferred to the Pantex Plant.

1947 - Today

Pantex Plant

Then...

In 1947, Mason & Hanger designed (A/E) the Pantex Plant. For more than four decades (1956-2011), we provided management & operations (M&O) services at the mission-critical plant.

From the very onset, protecting our employees, the general public and the plant has been our number one priority, and training has played a pivotal role in maintaining this commitment. In the late 1950s, we proudly designed Pantex’s education training center, a facility that improved the learning process through the use of visual aids and movies produced in onsite television studios.

Today...

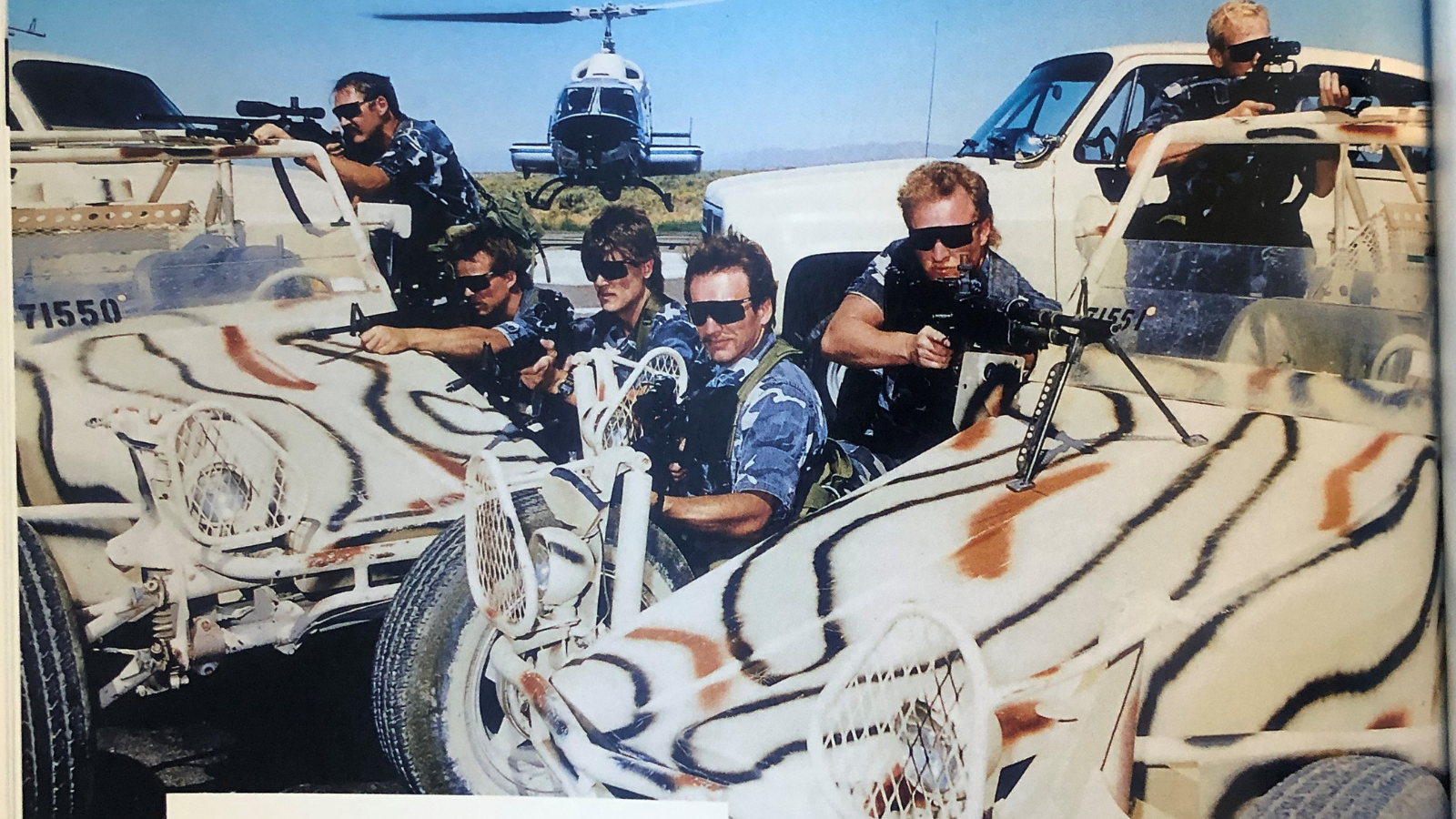

We provide the award-winning protective force operations in support of the Pantex site including perimeter control, static guards, access control, Special Response Teams, Fire, EMS, and Hazmat operations. Our successful protective force operations have earned three NNSA awards for security operations, the Bradly A. Peterson Federal Contractor Security Professional of the Year, NNSA Security Manager of the Year Award, and the NNSA Outstanding Security Team or Group award.

1947- 2023

Nevada National Security Site

In 1947, Mason & Hanger started designs and worked for the Nevada Nuclear Weapons Test Site.

Through 1956, we served as Architects and Engineers for AEC's Nevada Test Site for nuclear weapons, developing some of the nation's leading technologies for designing structures to resist dynamic loading. The structures include 300’ and 500’ detonation towers and Gravel Gerties.

Affectionately known as Gravel Gerties – a reference to a character in Dick Tracy, a popular comic series of the time – this leading-edge technology soon became a standard feature of the nuclear production, assembly and storage processes.

For more than five years, SOC delivered safeguards and security protection operations at the Nevada National Security Site (NNSS), including protective force services, tactical training, physical security systems and technical security engineering, performance testing, human reliability program, environmental safety, health, and quality assurance, resource management, labor relations, logistics support, and records management.

1980-2001

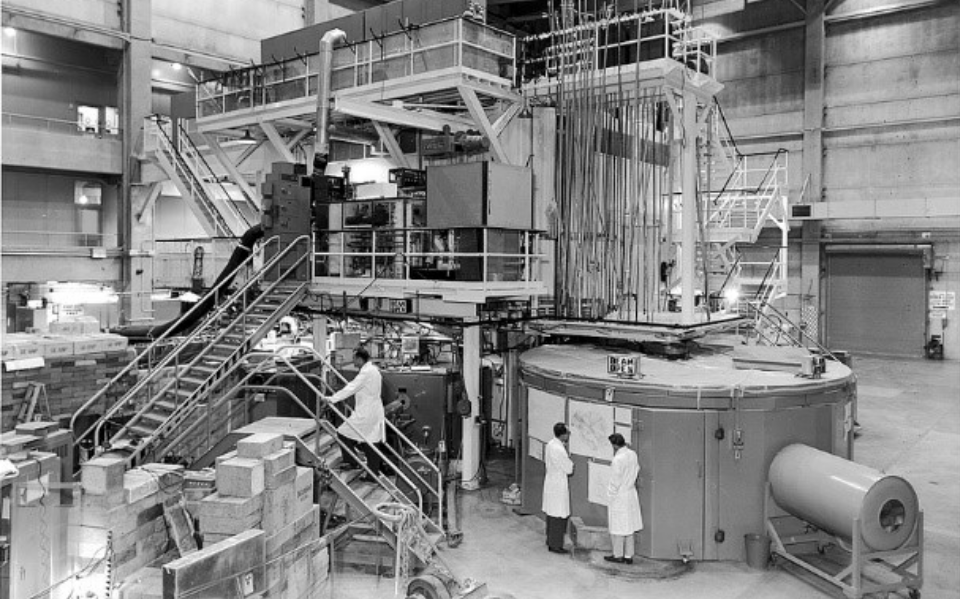

More Than 100 Contracts for DOE

We completed more than 100 contracts for the Department of Energy at various sites and major national laboratories throughout the United States.

As part of this mission support, for more than 20 years, we provided Protective Force operations at Los Alamos National Laboratory, one of the largest national laboratories supporting DOE, safeguarding national security assets in a federally-funded research and development environment.

Today

Safeguards, Security, Emergency Services, O&M, Maintenance & Construction, to support and protect U.S. National Security

Currently, we fill a critical role in protecting the research and development that supports the nation’s nuclear deterrent and other important national security missions. We deliver award-winning security and emergency services operations solutions for several U.S. Department of Energy (DOE) sites, providing protection of personnel, equipment, facilities, and assets around the clock. In addition, our Maintenance & Construction division is supporting Facilities Enhancement Projects at the Oak Ridge National Laboratory’s (ORNL).

DOE Sites/Operations Currently Supported:

The Strategic Petroleum Reserve • Pantex Plant • Oak Ridge National Laboratory • Several National Laboratories