Fossil Success Stories

Featured Story

Overcoming Accelerated Schedules & Unexpected Challenges

An unexpected chain of events led to moving up a confidential client’s scheduled 5-week outage by one week. Day & Zimmermann and the client’s plant team worked closely and acted quickly to move up the mobilization of required staff, craft, and tools to safely complete the necessary outage projects. The outage was completed ahead of the planned schedule while utilizing fewer craft hours than the original budget for a net savings to the customer of approximately 5%.

D&Z Completes Building Expansion and Renovation of Union Hall in Alabama

Day & Zimmermann safely completed a 5,000-square-foot renovation, 2,500 square-foot office space addition, exterior refurbishment, and other convenience and aesthetic improvements for the Operating Engineers Local 312 union hall near Birmingham, Alabama.

Submerged Flight & Dry Flight Conveyor Installations

Day & Zimmermann provided supervision, craft labor, and construction services to install a United Conveyor-supplied Submerged Flight Conveyor (SFC) system and Dry Flight Conveyors (DFC) at MidAmerican’s Neal Energy Center Unit 3 during the spring 2018 outage.

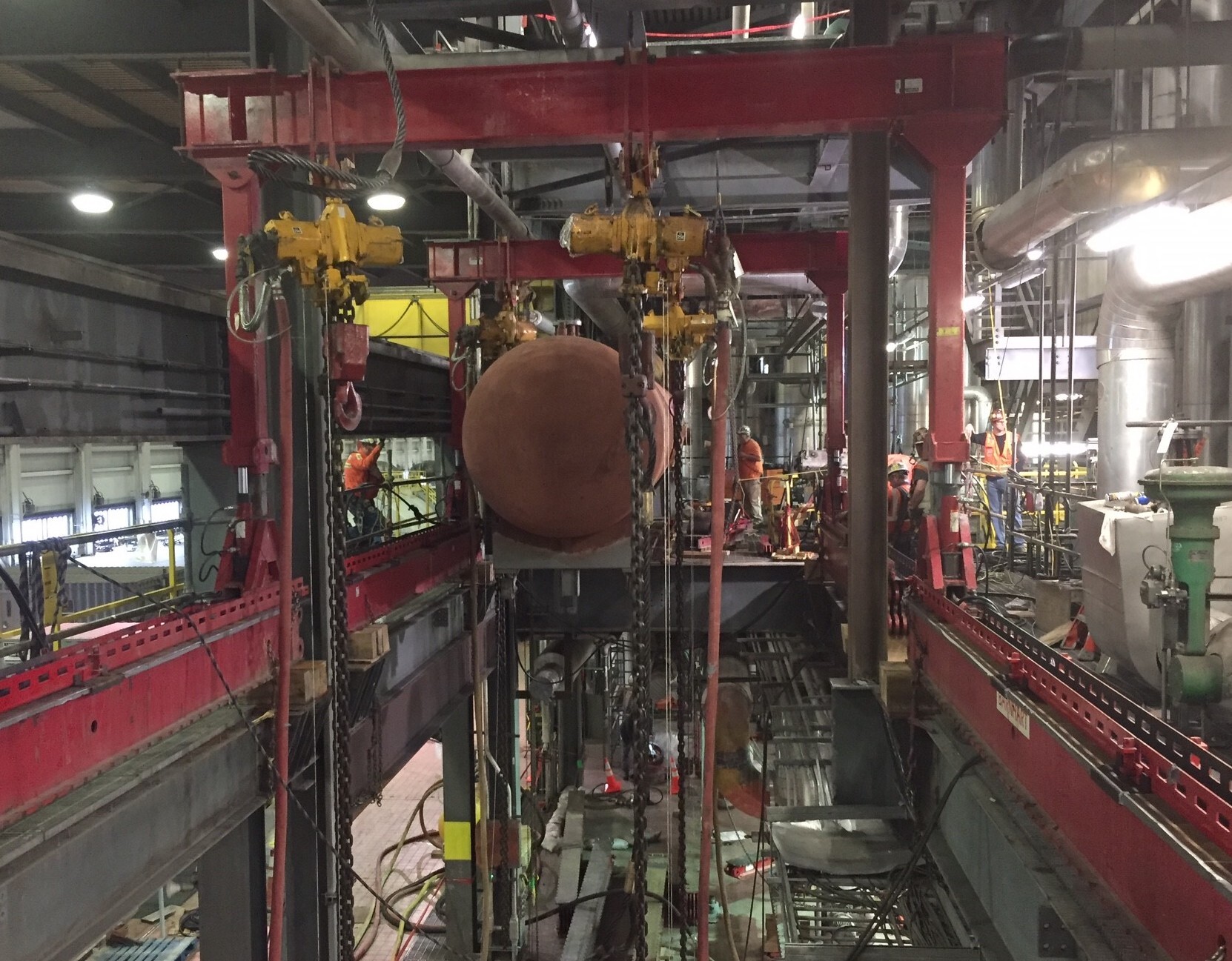

Efficient Removal Technique Implemented for Feedwater Heater Replacements

Using engineering and rigging expertise, D&Z successfully removed and replaced two feedwater heaters with only inches to spare.

Combined-Cycle Power Plant Construction Completion & Commissioning

D&Z team performed final construction and commissioning of a 440 MW combined-cycle gas plant set to serve 25,000 customers in the Pacific Northwest, meeting strict, federally mandated first-fire date, safely and on-budget.

D&Z Excels on Large Boiler Project, Awarded Additional Scopes

D&Z completed a large-scale boiler nose tube replacement ahead of schedule at a plant in the Northeast during their planned spring outage, leading to kudos from the customer and the award of additional scope on-site.

One Year Later: Partnership Continues to Grow Stronger, More Profitable

After one year as the sole maintenance contractor for a large Mid-Atlantic utility company, Day & Zimmermann has helped the customer to increase their productivity and improve their fleet’s quality and safety cultures, all while completing a full year with zero recordables at their largest coal-fired plant.

L-83 Boilermakers shine on Jeffrey Energy Center outages

Boilermakers employed by Day & Zimmermann are demonstrating their skills at Westar Energy’s Jeffrey Energy Center in St. Marys, Kansas, where crews are working the Spring 2017 outage on Unit 1. The job follows on the heels of the Unit 2 fall outage, successfully completed late last year. Jeffrey Energy Center is the largest fossil power generation plant in Kansas, with three units rated at a combined 2,155 MW.

Elevating Standards: Exceptional Performance at Harrison Power Station

FirstEnergy needed critical work done to the boiler and penthouse at Harrison Power Station, a coal-fired plant in West Virginia. Day & Zimmermann’s union welding team executed 4,831 x-ray welds with only 19 repairs needed. translating to a remarkably low reject rate of just 0.39%. In the industry, where craft work on intricate boilers and within demanding environments, a 3% to 5% reject rate is the norm, which would have resulted in 130 to 240 repairs.